As part of our ongoing commitment to innovation, operational excellence, and Industry4WRD initiatives, VG Offshore Containers International is proud to announce the successful implementation of Monitor ERP and full integration with AUK Industries’ IoT platform. This powerful synergy marks a major milestone in our digital transformation journey, delivering end-to-end visibility, control, and optimization across our manufacturing operations

Advancing with Industry4WRD

The Fourth Industrial Revolution is reshaping the manufacturing landscape, and at VG Offshore, we are embracing the change. With support from the Industry4WRD Readiness Assessment and a clear digital roadmap, we have taken decisive steps to digitalize core functions, automate data collection, and gain real-time insights into production efficiency, quality, and machine utilization.

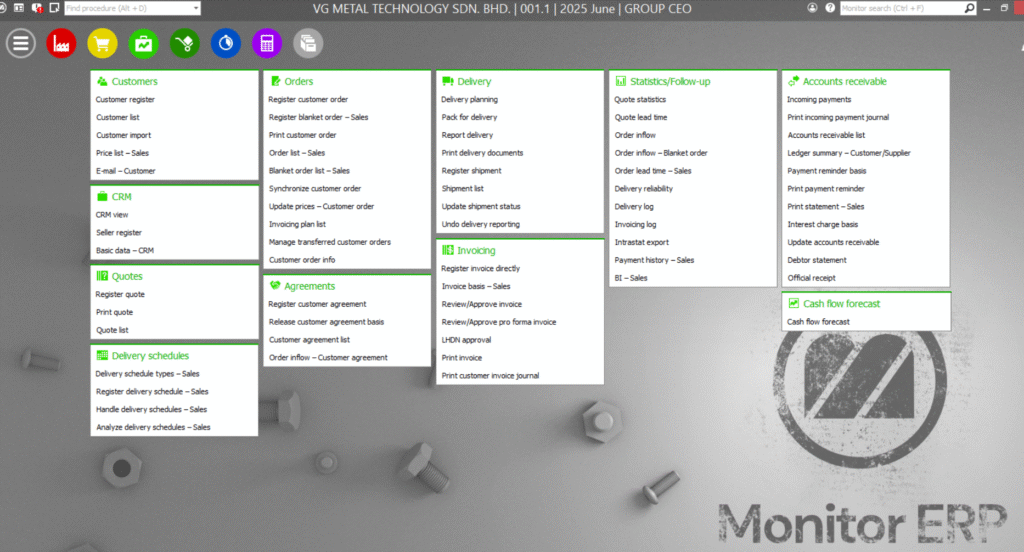

Why Monitor ERP?

Monitor ERP was selected as our backbone enterprise resource planning system for its comprehensive manufacturing capabilities and deep industry alignment. It offers full integration of all key business functions, including:

- Production planning & control

- Inventory and warehouse management

- Sales and purchasing

- Quality management

- Finance and costing

By standardising processes across departments and eliminating data silos, Monitor ERP gives our teams a unified, accurate, and real-time view of operations—from order to delivery.

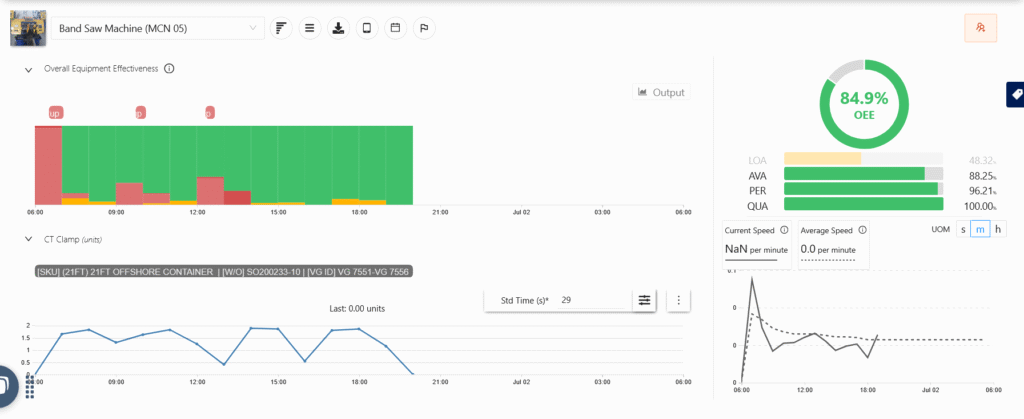

The Role of AUK Industries IoT

To enhance visibility at the shop floor level, we partnered with AUK Industries, a leader in Industrial IoT (IIoT) technology. Their system enables:

- Real-time machine data acquisition

- Production performance tracking

- Predictive maintenance insights

- Downtime analysis and root cause reporting

Through sensors and edge devices installed across our machines, data is collected automatically—eliminating manual recording and ensuring accuracy.

A Fully Integrated Digital Ecosystem

What sets this implementation apart is the seamless integration between Monitor ERP and AUK Industries’ IoT platform. Data captured from the shop floor flows directly into our ERP system, creating a closed-loop feedback mechanism. This enables:

- Instant comparison of planned vs actual performance

- Automated triggering of alerts and corrective actions

- Data-driven decision-making at both operational and management levels

- Continuous improvement through insights from live dashboards and analytics

In short, our team can now monitor, respond, and improve operations proactively—with full alignment between physical processes and digital systems.

Delivering Value to Our Clients

For our clients, this transformation means:

- Greater production reliability and transparency

- Improved lead time accuracy and delivery commitment

- Higher consistency in product quality

- Competitive pricing through optimised resource usage

At VG Offshore, we believe that adopting smart manufacturing technologies is not just a matter of staying relevant—it’s about leading the way. This integrated system is not the end of the journey, but a strong foundation for further innovation, such as AI-driven insights, advanced analytics, and sustainability metrics.

We thank our partners at Monitor ERP and AUK Industries for their collaboration, and we look forward to sharing the benefits of this transformation with all our stakeholders.

VG Offshore Containers International—Engineering Excellence, Digitally Empowered.